Custom Box Build

Assembly Services

Box build assembly in electronics manufacturing involves integrating various electronic components into an enclosure or housing to create a finished product.

In addition to PCB assembly services, we are also an electronic box manufacturer, providing a full range of electrical and mechanical box build assembly services tailored to your unique requirements. Our offerings include sub-system and complete box/system assembly services.

With extensive experience and state-of-the-art capabilities, we deliver a total turnkey manufacturing solution for even the most complex and configurable box build requirements. We are flexible in accommodating turnkey, consignment, and hybrid material solutions based on customer preferences.

Regardless of the production volume, we offer OEM customers comprehensive box build services, including build-to-order (BTO), configure-to-order (CTO), software configurations, loading, and final testing to meet exact specifications.

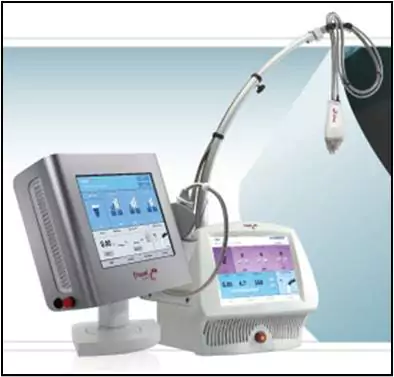

Examples of Box-Build Assembly & System Integration We have successfully assembled products such as medical devices, optical networking equipment, military-grade portable servers, WiMax wireless routers, electric vehicle charging stations, and more.

We provide a full electrical and mechanical box build assembly service tailor made to your needs.

Box Build Assembly is an electromechanical assembly process, include:

Providing the right information up front will help you get the job done right at the first time.

Please click the question to get the answer.

Box build assembly involves assembling and integrating electronic components within an enclosure to create a functional product.

It allows for the creation of complete, fully functional electronic devices by incorporating various components within a housing.

Questions might involve ISO certifications, assembly capabilities, quality control measures, and experience with similar projects.

Enhance assembly efficiency by optimizing workflows, ensuring high standards of assembly, and utilizing best practices.

ISO certifications ensure quality and compliance in the assembly process, reflecting the manufacturer's adherence to industry standards.

PCB assemblies are pivotal in connecting electronic components, enabling functionality within the device.

Yes, integrating components into an enclosure streamlines the production of finished products, enhancing efficiency.

These steps might include design, sourcing components, PCB assembly, testing, box build assembly, and quality control.

SMT assembly might be a component of box build assembly, contributing to the integration of surface-mount components on PCBs.

FAQs provided by manufacturers offer insights into the PCB manufacturing and assembly process.

Contact Information: Sparqtron Corporation

Tel: 1-510-657-7198 EXT. 200, eMail: info@sparqtron.com

Address: 5079 Brandin Court, Fremont, California CA 94538, USA

(In Silicon Valley, San Francisco Bay Area, near San Jose, California)