PCB Circuit Board Repair

BGA Rework Reballing

Printed circuit board repair and BGA (Ball Grid Array) rework/reballing are complex services that can pose significant challenges, especially for inexperienced EMS vendors. Inadequate handling may lead to damage of valuable engineering prototypes, jeopardizing your engineering timelines and New Product Introduction (NPI) schedules. Trust our expertise to deliver quality solutions.

We offer a comprehensive range of PCB repair services, including:

Driven by over three decades of electronics manufacturing expertise, our SVP of Engineering and Manufacturing stands as a pioneer in quick-turn PCB repair solutions. With a background managing global NPI operations at top-tier EMS companies, their leadership ensures efficient and effective handling of even the most intricate PCB repairs.

Our team's proven proficiency has established us as a trusted partner for Silicon Valley engineers. We leverage advanced techniques and a deep understanding of PCB technology to deliver repair services that extend product lifecycles and minimize downtime.

Always follow safety precautions, use proper tools, and refer to guides for detailed PCB repair procedures.

We provide high-quality, reliable 24 hrs. Quick-Turn PCB repair and BGA rework services. Engineers in the Bay Area trust our expertise and rely on us for their critical engineering change orders (ECOs), enabling them to meet tight deadlines without the need for PCB board respins if possible.

Success Story: High Quality and Fast Engineering Service

Engineers at the leading networking company in Silicon Valley opt to pay for Sparqtron’s rapid pcb repair services rather than using the free repair services offered by the vendor who manufactured it. This choice illustrates a clear preference for quality and efficiency over cost savings, showcasing the value they find in Sparqtron’s engineering expertise. By investing in these services, they ensure faster operational readiness for their pcb prototypes, which is crucial for maintaining performance and competitiveness in their field.

We provide a high-quality rework and reballing solution tailored to customers' requirements. Our BGA rework and reballing services address issues like solder ball damage and connectivity problems. The process involves:

Specialized equipment and skilled technicians are essential for ensuring quality connections and reliability. We offer quick-turn pcb repair services within 24 hours.

We can cost effectively and quickly reball a single BGA or at volume. We are also capable of reworking precision complex components such as shown below:

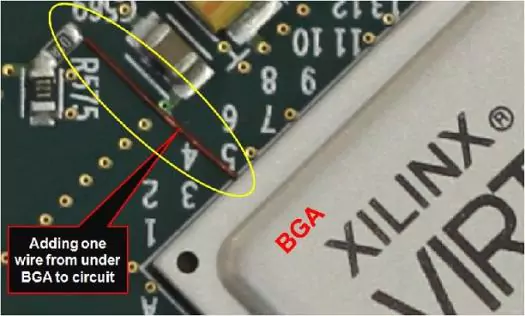

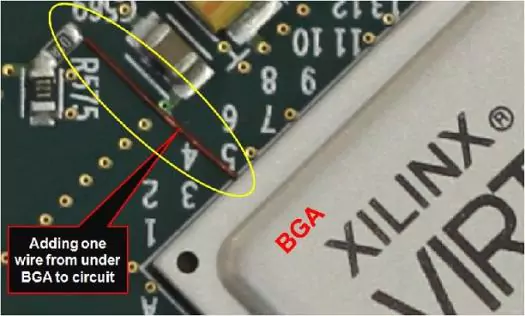

We can do engineering changes and modifications in circuit paths on printed circuit boards at BGA sites and other locations. We can save customer the costs for re-spinning and re-building PCB printed circuit boards with our engineering change order service (ECO), saving you both time and money in the most time critical prototype cycle. It helps to catch up with your tight development schedule.

Modifying circuit paths at BGA locations requires advanced expertise in precision engineering. This process involves specialized milling tools and meticulous execution, ensuring accurate adjustments. Our team integrates radiographic inspection, high-precision PCB milling, and careful component placement—such as pads, traces, and jumpers—to achieve flawless rework. The outcome is determined by the technician’s skill and attention to detail, ensuring reliable performance.

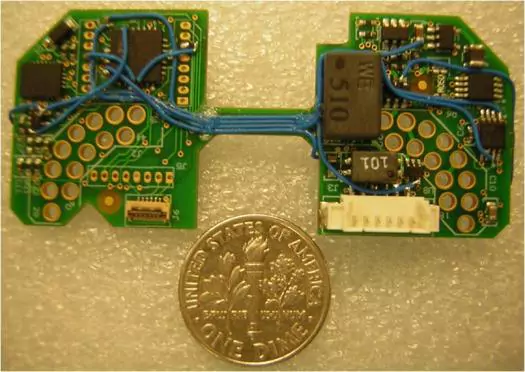

Integrating multiple jumper wires on a compact PCB requires precision and efficiency. Our team successfully implemented six wires on a high-density board, completing 100 units within a single day. This rapid turnaround helped maintain our customer’s New Product Introduction (NPI) timeline, ensuring no delays in their development cycle. By optimizing wire placement and execution, we deliver reliable modifications tailored to demanding project requirements.

Facing an urgent trade show deadline, our client’s engineering team needed an immediate solution. Without time for a PCB redesign, we provided a critical intervention by integrating 26 jumper wires across both sides of a miniature PCB. This strategic rework enabled a functional prototype, securing their presentation and preserving their team’s position. Our expertise in high-stakes circuit modifications ensures mission-critical projects stay on track, even under extreme time constraints.

Accredited Service Center: We operate a fully accredited warranty and repair service center, equipped with an RMA tracking system to monitor the status of each repair and fix. This system provides customers with the reassurance that repairs will be handled promptly, significantly reducing costs associated with idle inventory and enhancing satisfaction for their end customers.

Swift and Efficient Service: Unlike many EMS providers who take a long time to repair and return customer goods, we ensure swift and efficient service. When you do business with us, you don’t have to worry about delays.

Our Expertise: Our customers highly appreciate our skill, quality, and speed in PCB repair, BGA rework and reballing. Try us, and your satisfaction is guaranteed. We are located in the Bay Area, Silicon Valley, California, USA, near San Jose.

In summary, our PCB repair services offer an efficient solution for implementing engineering changes and modifications in circuit paths, aiming to save costs and time while meeting critical prototype development cycles.

Experience the quality, speed, and expertise that have earned us recognition from top CPU and networking OEM companies. Contact Us today for a free quote!

Please click the question to get the answer.

BGA reballing is a method for repairing BGA components with damaged or missing solder balls without replacing the entire component.

Solder balls and universal reballing kits are available for purchase.

Component removal, site cleaning, reballing, and other meticulous steps are involved in successful BGA rework.

We offer comprehensive PCB rework and repair solutions by very skilled technicians.

Original AMTECH NC-559-ASM Flux is a no-clean flux used in BGA rework.

After BGA removal, the site must be prepared for replacement, ensuring proper attachment of the replacement BGA.

Contact Information: Sparqtron Corporation

Tel: 1-510-657-7198 EXT. 200, eMail: info@sparqtron.com

Address: 5079 Brandin Court, Fremont, California CA 94538, USA

(In Silicon Valley, San Francisco Bay Area, near San Jose, California)