Turnkey Manufacturing

Material Management

For electronics manufacturers, materials represent the single largest cost factor, often exceeding 50% of the total product cost. Efficient procurement and management of these materials are crucial for achieving profitability and staying competitive.

The material procurement and management for electronics manufacturing encompass many critical processes from sourcing, acquiring, forecasting, and handling materials essential to electronic production. Below is a highlight of our activities for supporting our customers:

We specialize in providing comprehensive turnkey and material management solutions.

Effective production planning is the cornerstone of manufacturing success, beginning with meticulous procurement and management of materials. Our highly experienced production planning team collaborates closely with customers to ensure the availability of all necessary materials, equipment, and labor precisely when needed.

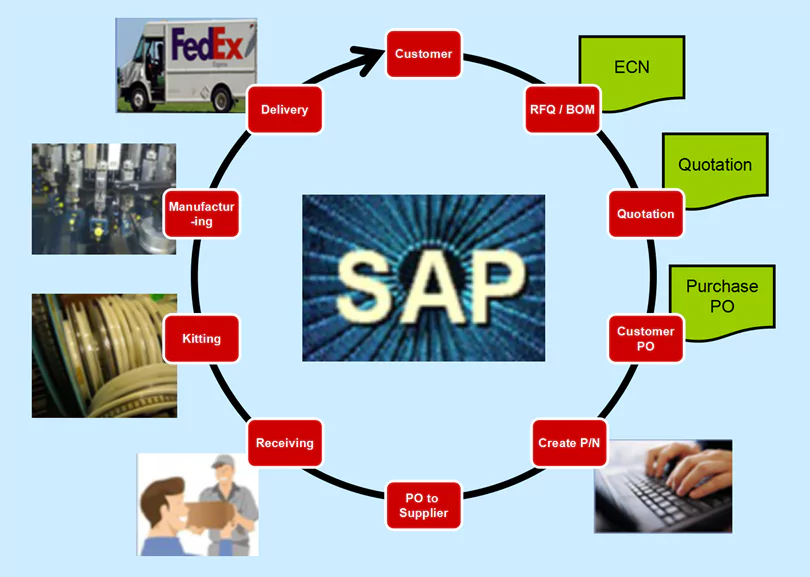

Utilizing the robust SAP ERP system, we oversee and control the entire process, ensuring the timely manufacture of prototypes, small-batch, and volume production. By leveraging our extensive global supply chain network, we can significantly reduce material costs. We accommodate consignment, turnkey, and mixed manufacturing projects.

By partnering with us, you can streamline your production processes, reduce costs, and bring your products to market faster. Trust us to be your reliable partner in achieving manufacturing excellence.

The intricate dance of the global electronics manufacturing supply chain faces a constant tango of challenges. Here's a breakdown of some key hurdles:

Remember, these challenges are not isolated. They often intertwine and create a complex web of disruptions. That is why you need to find a professional EMS partner who has a global connection and experience to better handle the material management of your products. Sparqtron, with more than 20 years of experience, is the best vendor of choice.

Sourcing and Procurement: Involves global sourcing, meticulous selection, and acquisition of electronic components with dedicated project managers ensuring manufacturing success.

Material Procurement Process: Encompasses sourcing materials vital for electronic manufacturing, ensuring timely availability and quality while managing costs.

Electronics Materials Planning: Essential for Electronics Manufacturing Services (EMS) and Original Equipment Manufacturers (OEMs), emphasizing distinct approaches in managing materials and procurement.

Purchasing Management: Vital analysis of raw material procurement in the electronic manufacturing industry, emphasizing its significance and contents.

Challenges in Global Electronics Manufacturing Supply Chain: Addressing current challenges faced by the global electronics manufacturing supply chain, such as logistics and procurement hurdles.

Best Practices for OEM Electronics Purchasing: Outlines best practices for OEM buyers and planners in managing requests, quotes, and procurement of services for electronics manufacturing.

Supply Chain Management: Emphasizes the necessity of smooth logistics planning and coordination among teams and Contract Manufacturers (CM) for electronics manufacturing.

Overcoming Component Procurement Challenges: Highlights challenges like component obsolescence and strategies to mitigate risks in electronic component procurement.

Contract Electronic Manufacturing Services (EMS) Procurement: Involves experts supporting electronic component engineering, management, and certification.

EMS Supply Chain Management Solutions: Includes managing obsolescence, material procurement, global networks, and ensuring materials' quality control in a smart supply chain.

Procurement & Supply Chain Services: To support manufacturing activities, providing various procurement and inventory management solutions.

These practices collectively ensure efficient, cost-effective, and quality-driven material procurement and management in electronics manufacturing.

Materials management is an aspect of supply chain management and planning. The primary purpose of materials management is to ensure that manufacturers have all the raw materials they need to make goods.

Materials management also focuses on ensuring that no components are wasted and optimizing inventory maintenance and management. While materials management requires understanding what materials are needed and where to source them, it is also heavily involved in inventory management and storage.

We offer a total solution to material management to meet the unique requirements of our customers. Our experienced procurement and logistic professionals are dedicated to understanding the material and supply chain needs of every customer. We use the SAP ERP system to manage customer demands and the supply chain of materials, achieving cost-effectiveness, on-time delivery, and minimum inventory levels for our customers.

ERP provides an integrated real-time view of our business processes. The system shares data across all our departments, facilitating our team to be responsive and effective in supporting our customers.

We use SAP to manage key business processes, such as planning, ordering, purchasing, scheduling, engineering, manufacturing, delivering, and inventory management, etc.

Inventory management provides a holistic view, focusing on stock levels, tracking, and movement across the supply chain. It encompasses acquisition, tracking, shipping, and ensuring product availability. Inventory management focuses on forecasting, demand planning, and overall stock control.

Warehouse management involves the physical operations within a warehouse. It optimizes layout, controls inventory tracking, executes picking and packing, and manages receiving processes and order fulfillment.

We have some customers who have multiple CMs. Most of their engineers prefer to run their new jobs with Sparqtron because our team always plans ahead and provides the earliest material availability, allowing engineers to complete their products much quicker than doing the job elsewhere.

Please click the question to get the answer.

Key aspects include inventory control, demand forecasting, supplier relationship management, quality control, and efficient logistics.

Challenges include supplier reliability, price fluctuations, inventory inaccuracies, demand volatility, and maintaining quality standards.

Technology like inventory management software, IoT sensors, and data analytics improves efficiency, enhances visibility, and streamlines processes in procurement and material handling.

Goals involve cost savings, ensuring the right materials at the right time, reducing lead times, fostering supplier relationships, and maintaining quality standards.

Effective material management positively influences production schedules, cost management, product quality, and overall operational efficiency.

Contact Information: Sparqtron Corporation

Tel: 1-510-657-7198 EXT. 200, eMail: info@sparqtron.com

Address: 5079 Brandin Court, Fremont, California CA 94538, USA

(In Silicon Valley, San Francisco Bay Area, near San Jose, California)