Custom Box Build and Assembly Services

Box build assembly in electronics manufacturing involves integrating various electronic components into an enclosure or housing to create a finished product.

Other than PCB assembly services, we are also an electronic box manufacturer, we provide a full electrical and mechanical box build assembly service tailor made to your unique requirements. We offer sub-system and complete box/system assembly services.

We are well equipped and experienced in providing a total turnkey manufacturing solution for highly complex and configurable box build requirements. We are flexible to accept turnkey, consignment, and hybrid material solutions per customer requirements.

Whatever volume you want to build, we provide OEM customers with complete box build services, with build-to-order (BTO), configurate-to-order(CTO), software configurations, loading, final test to specifications.

Box-Build Assembly & System Integration

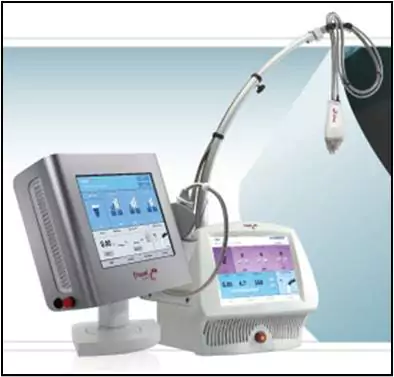

Examples of some products we have built including medical device equipments, optical networking products, military portable server, WiMax wireless router, electric vehicle car charging station, etc.

Examples of our Box Build Assembly Projects

Military Portable Server

Medical Device

Medical Laser Equipment

Box Build Assembly Process

Box Build Assembly is an electromechanical assembly process, include:

- Sub-Level Product Assembly

- Design and engineering for mechanical components (injection molding, die casting, etc.)

- Enclosure Fabrication,

- installation of components and sub-assemblies

- Routing of Cabling or Wire Harnesses,

- System Level Assembly

- Software Loading and Product Configuration

- Functional Testing

- Complete Product Testing & Burn-In

- Custom testing systems with integrated software and hardware solutions.

- Packaging & Labeling

- Warehousing, Order Fulfillment, and Traceability

- Custom tooling and fixtures

- Build-to-order and configure-to-order (BTO & CTO)

- Direct shipment to point of sale

- Full turnkey solution

Software Loading and Functional Test after Box Build

Box Build

Software Loading

Box Build

Assembly-test

Live Burn-In Test

Required Information for a Box Build Assembly Quote

Providing the right information up front will help you get the job done right at the first time.

- BOM (Bill of Material) for box level components (consign or turnkey)

- 3D CAD box assembly drawing

- Circuit diagrams (Electrical systems schematics)

- Test procedure and estimated time

- Tooling and fixtures

- Special testing equipment

- Size and weight of the unit

- Detailed build instructions

- Sample unit if available

- Testing: basic electrical safety testing, functionality testing

- Acceptance Criteria

- Any other special instructions

Please click the question to get the answer.