Materials Management and Logistics

for Electronics Manufacturing

For electronics manufacturers, materials represent the single largest cost factor, often exceeding 50% of the total product cost. Efficient procurement and management of these materials are crucial for achieving profitability and staying competitive.

The Material procurement and management for electronics manufacturing encompass many critical processes from sourcing, acquiring, forecasting and handling materials essential to electronic production. Below is to highlight our activities for supporting our customers:

Sourcing and Procurement:Involves global sourcing, meticulous selection, and acquisition of electronic components with dedicated project managers ensuring manufacturing success.

Material Procurement Process: Encompasses sourcing materials vital for electronic manufacturing, ensuring timely availability and quality while managing costs.

Electronics Materials Planning: Essential for Electronics Manufacturing Services (EMS) and Original Equipment Manufacturers (OEMs), emphasizing distinct approaes in managing materials and procurement.

Purchasing Management: Vital analysis of raw material procurement in the electronic manufacturing industry, emphasizing its significance and contents.

Challenges in Global Electronics Manufacturing Supply Chain: Addressing current challenges faced by the global electronics manufacturing supply chain, such as logistics and procurement hurdles.

Best Practices for OEM Electronics Purchasing: Outlines best practices for OEM buyers and planners in managing requests, quotes, and procurement of services for electronics manufacturing.

Supply Chain Management: Emphasizes the necessity of smooth logistics planning and coordination among teams and Contract Manufacturers (CM) for electronics manufacturing.

Overcoming Component Procurement Challenges: Highlights challenges like component obsolescence and strategies to mitigate risks in electronic component procurement.

Contract Electronic Manufacturing Services (EMS) Procurement: Involves experts supporting electronic component engineering, management, and certification.

EMS Supply Chain Management Solutions: Includes managing obsolescence, material procurement, global networks, and ensuring materials' quality control in a smart supply chain.

Procurement & Supply Chain Services: to support manufacturing activities, providing various procurement and inventory management solutions.

These practices collectively ensure efficient, cost-effective, and quality-driven material procurement and management in electronics manufacturing.

Materials management is an aspect of supply chain management and planning. The primary purpose of materials management is to ensure that manufacturers have all the raw materials they need to make goods.

Materials management also focuses on ensuring that no components are wasted and optimizing inventory maintenance and management. While materials management requires understanding what materials are needed and where to source them, it is also heavily involved in inventory management and storage.

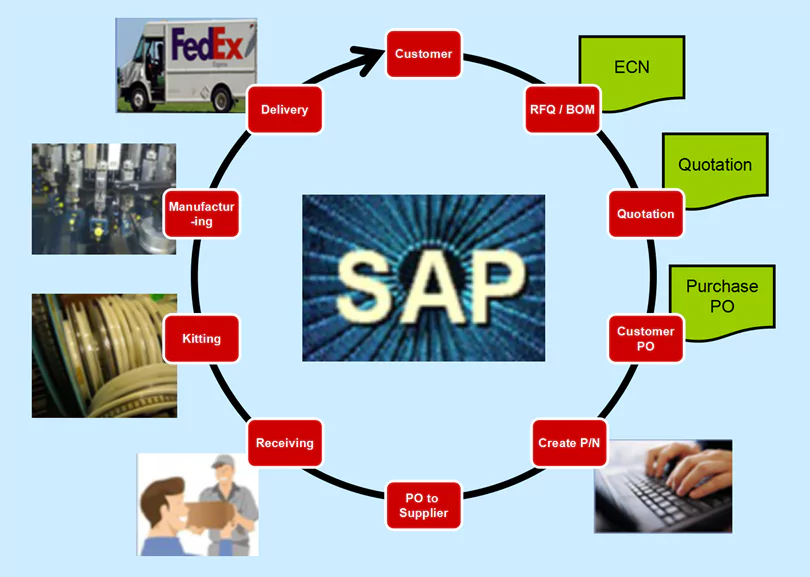

We offer a total solution to material management to meet the unique requirements for our customer. Our experienced procurement and logistic professionals who is dedicated to understanding the material and supply chain needs of every customer. We use SAP ERP system to manage the customer demands and the supply chain of materials, to achieve cost effectiveness, on time delivery and minimum inventory level for our customers.

SAP ERP for Business Management

ERP provides an integrated real-time view of our business processes, the system shares data across all our departments which facilitates our team being responsively and effectively in supporting our customers.

We use SAP to manage key business processes, such as Planning, ordering, Purchasing, scheduling, engineering, manufacturing, delivering, and Inventory Management, etc.

Turnkey, Consignment and Hybrid Material Solutions

- Provides material engineering services to your engineering team and release their burden on material sourcing.

- Component Engineering-Part number assignment, AVL creation and management, Component Qualifications and Alternative Sources Suggestion Capability.

- Capability to perform quick turn “what if” scenarios

- Provide Audit Report on each Production Work Order in details.

- Distinguish consignment and turnkey parts through SAP part numbers with information such as AVL/AML for supply base management

- Leverage our global material sourcing capabilities in Taiwan, China and USA.

Order Fulfillment

- Manage the inbound logistics with materials from many suppliers coming into manufacturing sites around the world.

- Manage the outbound logistics by shipping product to customers’ facilities in various locations or even direct ship to point of use.

Inventory Management

Inventory Management provides a holistic view, focusing on stock levels, tracking, and movement across the supply chain. It encompasses acquisition, tracking, shipping, and ensuring product availability. Inventory management focuses on forecasting, demand planning, and overall stock control,

Warehouse Management

Warehouse Management involves the physical operations within a warehouse. It optimizes layout, controls inventory tracking, executes picking and packing, manages receiving processes and order fulfillment .

Speed up the Development Schedule for Engineers

We have some customers who have multiple CMs, most of their engineers only prefer to run their new jobs with Sparqtron, because our team always plan ahead and provide the earliest material availability, so that the engineers can complete their product much quicker then doing the job at other places.

Managing the Global Supply Chain Challenges

The intricate dance of the global electronics manufacturing supply chain faces a constant tango of challenges. Here's a breakdown of some key hurdles:

- Component Shortages: The Semiconductor Scarcity: The ongoing chip shortage remains a major headache. Increased demand for electronic devices, geopolitical tensions, and natural disasters can disrupt silicon production, leading to extended lead times and skyrocketing prices. Beyond Silicon: Shortages aren't limited to chips. Essential components like capacitors, resistors, and even passive filters can become scarce, bringing entire production lines to a halt.

- Geopolitical Volatility and Political Instability: Trade Wars and Tariffs: Trade tensions and tariff implementations can disrupt established supply chains, increasing costs and forcing manufacturers to rethink sourcing strategies. Political Instability can lead to production disruptions and logistical nightmares.

- Logistical Bottlenecks: Port Congestion and Shipping Delays: Global port congestion and limited container availability can lead to delayed shipments, missed deadlines, and increased transportation costs.

- Forecasting and Planning Difficulties: Rapidly Evolving Technology: Keeping up with the fast-paced advancements in electronics technology requires agile forecasting and planning to avoid overstocking obsolete components or underestimating demand for cutting-edge parts. Demand Volatility: Unpredictable changes in consumer preferences and market trends can lead to inaccurate demand forecasting, resulting in excess inventory or stockouts.

- Sustainability Concerns: Ethical Sourcing: Growing ethical concerns around raw material extraction and labor practices in certain regions can force manufacturers to re-evaluate their sourcing strategies and implement stricter ethical sourcing policies. Environmental Impact: The electronics industry generates significant e-waste. Implementing sustainable practices and managing e-waste responsibly are becoming increasingly important challenges.

Remember, these challenges are not isolated. They often intertwine and create a complex web of disruptions. That is why you need to find a professional EMS partner who has a global connection and experience to better handle the material management of your products. Sparqtron has more than 20 years experiences, is the best vendor of choice.

Material Procurement and Management - Q&A

Please click the question to get the answer.

Understanding the fundamentals and implementing efficient strategies in material procurement and management ensures streamlined operations, cost savings, and enhanced productivity.