Our PCB Assembly and Circuit Card

Assembly Services

In today’s dynamic electronics market, rapid product deployment is key to staying ahead. At Sparqtron, we specialize in delivering high-quality, mission-critical Printed Circuit Board Assembly (PCBA) and Circuit Card Assembly (CCA) services. Our proficiency in circuit board prototyping and quick-turn services accelerates your product’s time-to-market, helping you outpace the competition.

About PCBA and CCA

Printed Circuit Board Assembly (PCBA) involves the precise soldering and placement of electronic components onto a printed circuit board, transforming it into a fully functional device. This critical process serves industries such as consumer electronics, medical, automotive, and telecommunications.

Circuit Card Assembly (CCA)refers to a more specialized form of assembly, often required in high-complexity industries like aerospace, defense, military, and medical sectors. These industries demand the highest standards of reliability, making CCA essential for mission-critical applications.

Both PCBA and CCA ensure optimal component placement and robust connections, resulting in dependable, high-performance products.

Our Professional Services

Sparqtron offers a broad range of flexible, cost-effective solutions, from quick-turn PCB prototypes to full-scale production runs. Our turnkey services, supported by expert engineering and manufacturing teams, allow us to solve complex challenges that other providers may struggle with. Our dedication to excellence has earned us repeat business and strong referrals from satisfied clients.

Our Expertise in PCB Assembly

Our SVP of Engineering and Manufacturing brings over 30 years of experience in the electronics contract manufacturing industry, specializing in PCB assembly. They have led global NPI operations at renowned top tier EMS companies, ensuring the seamless transition from prototype to production. Their extensive knowledge in quick-turn PCB assembly has been instrumental in reducing time-to-market for our clients.

Our commitment to precision and efficiency in PCB assembly has earned us a distinguished reputation among Silicon Valley engineers. We leverage best practices developed over decades to deliver high-quality, reliable PCB assembly services that meet the stringent demands of the tech industry.

PCB Design and Layout Services

Our PCB design and layout services, in partnership with a globally recognized design house with over 28 years of experience, provide superior quality and service. We offer:

- PCB Layout

- Schematic Capture

- Component Placement

- Routing

- Thermal Analysis

- Power Integrity Checks

Whether you need a design from scratch or an upgrade to existing designs, our services ensure optimal performance and reliability.

PCB/CCA Fabrication, Assembly, and Manufacturing

Our PCB fabrication services involve creating the PCB foundation through processes like layering, etching, and adding copper traces. We cover:

- Quick-turn PCB Prototyping

- Quick-Turn Services for Small Batches

- Full-Scale Manufacturing

We collaborate with certified PCB fabrication manufacturers to meet specific project requirements, ensuring efficient, high-quality production. Our fast turn PCB assembly and fast turn circuit board manufacturing services are designed to meet urgent project deadlines, offering quick turn PCBs and fast turn prototype PCB board solutions.

Flexible PCB Solutions

We tailor our offerings to meet diverse needs, including:

- Quick-Turn Projects: Rapid turnaround with local manufacturers, sometimes within a day, perfect for quick turn PCB assembly needs.

- Complex PCB Projects: Specialized manufacturers for high-layer count PCBs and complex assemblies.

- Cost-Effective Solutions: Budget-friendly options from competitively priced manufacturers.

PCB/CCA Component Assembly Capabilities

Our capabilities include SMT/SMD, through-hole, and mixed-technology pcb assemblies. We specialize in:

- BGA, uBGA, 01005 Component Placements

- PoP (Package on Package) Assembly

- Leadless Device Assembly

We expertly handle complex PoP assemblies, ensuring precise BGA placements with pitches as fine as 0.25 mm.

Quick-turn Prototype PCB/CCA Assembly

We provide fast and reliable prototype PCB and CCA assembly services, allowing engineers and developers to efficiently test and validate their designs. This critical process helps identify errors and ensure functionality. Our services include prototype circuit board assembly, PCB prototype and assembly, and comprehensive prototype PCB assembly solutions.

Comprehensive PCB/CCA Assembly Process

The PCB assembly process involves several essential steps to ensure the successful creation of functional electronic devices:

- Pre-Assembly Preparation: Select appropriate components and finalize the PCB design. Unpack the received components and prepare them for loading into the Surface Mount Devices (SMDs) line.

- Solder Paste Application: A stencil is placed over the PCB, and solder paste is applied to the board pads where components will be mounted. After application, the stencil is lifted, leaving solder paste on the designated pads.

- Component Placement: This process includes board indexing, fiducial alignment, component pickup, centering, placement, and automated optical inspection (AOI). Each component is precisely positioned on the solder paste before moving to the next stage.

- PCB Positioning:

During board indexing, the PCB is aligned using fiducial marks to ensure accuracy at each assembly stage. The three main types of fiducial marks are:

- Panel Marks: Global marks on a multi-board panel.

- Global Marks: Fiducials on individual PCBs to locate all features.

- Local Marks: Fiducials for specific, precision-critical components.

- Soldering: The assembly is passed through a reflow oven where the solder paste melts and solidifies, securing the components to the PCB.

- Vision Inspection: Assembled boards undergo inspection for defects and quality assurance using techniques such as AOI (Automated Optical Inspection) and X-ray inspection.

- Testing: Final testing ensures that the assembled PCBs function correctly. This includes in-circuit testing (ICT) and functional testing. For more on "Inspection and Testing," please

These steps are crucial in producing reliable, high-quality PCB assemblies tailored to meet the specific requirements of various industries.

Our Experience and Expertise: PCB Assembly Projects

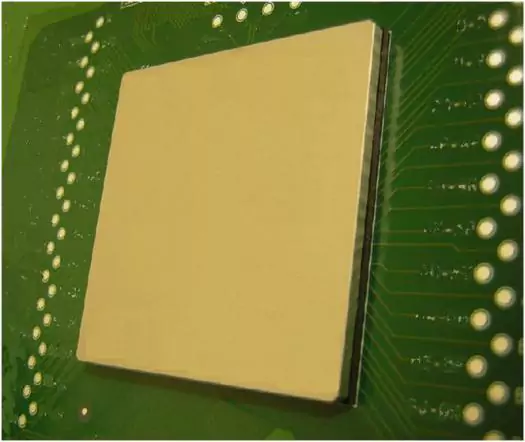

Very Large Complex

PCB Board Assembly

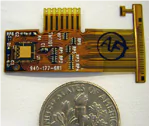

Very Tiny and Difficult

Flex PCB Assembly

High Density and Heavy BGA Assembly

Highlights of Our PCB and CCA Services

- Design Review: Comprehensive DFM/DFT reviews to prevent costly errors and ensure smooth production.

- Flexible Support: Adaptive to engineering changes, ensuring your project incorporates the latest updates.

- Advanced Capabilities: Expertise in handling 01005 SMT/SMD components and PoP assemblies.

- Quick Turnaround: Rapid prototyping often within 24 hours, ideal for urgent design needs.

- Flexible Assembly Options: Choices for consignment, turnkey, and hybrid solutions to suit specific requirements.

- Build Types: From low-volume to high-volume and full-scale manufacturing.

- PCB Types: Single-Sided, Double-Sided, Multi-Layer, Rigid, Flex, HDI, Rigid-Flex, Alumina Ceramic, and Aluminum PCBs.

- Lead-Free and Leaded Assembly: Offering both Pb-Free, RoHS-compliant, and traditional lead-based solder processes.

Innovation and Technology

At Sparqtron, we stay at the forefront of technological advancements in the electronics manufacturing industry. Our investment in state-of-the-art equipment and continuous improvement initiatives enables us to offer cutting-edge solutions and maintain a competitive edge.

(A) Manufacturing and Testing Equipment for PCB Assembly

- SMT/SMD placement equipment

(3 lines with 5 CPs, 01005 footprint, PoP)

- Thru-Hole Lines

- Screen printer

- Epoxy dispenser

- Reflow oven

- Wave soldering

- Cleaning system

- BGA rework station

- 3D X-Ray system

- AOI inspection system

- Flying Probe

- In-Circuit Test System

(B) New PCB Assembly Equipment Added Annually, below are the recently added advanced equipments:

FUJI:AIMEX III,

High Speed Multi-placer

Mirtec MV-6 Omni 3D AOI

In-Line AOI Machine

(high resolution)

Trident ZDO High-Yield

Cleaning System

Nordson Dage 3D X-Ray

Quadra 5 Inspection System

Inspection for PCB Assembly and CCA

Advanced 3D X-Ray (Ultra High Resolution)

Nordson DAGE Ruby X-ray

Inspection System

Nordson Quadra™ 5 X-ray

Inspection System

Free 3D-Xray PCBA Debugging Support for New Engineers

Call for a free Testing

PCB assembly, circuit card assembly, PCB circuit board Ball Grid Array (BGA) and Chip Scale Packages (CSP) are extensively utilized in the manufacturing of electronic devices. At our facility, we employ the Nordson DAGE Ruby X-ray and Nordson Quadra 5 X-ray Inspection Systems for ultra-high-resolution inspections testing.

The X-ray Inspection System of choice:

The X-ray Inspection System of choice:

Quadra™ 5 is the X-ray inspection system of choice for submicron applications such as PCB and semiconductor package inspection, counterfeit component screening and finished goods quality control. The Nordson DAGE XD7600NT and Nordson Quadra 5 stand as exceptional machines designed for a comprehensive range of PCBA inspection tasks. These systems serve as invaluable tools for aiding R&D engineers in diagnosing highly complex PCB assemblies, thereby accelerating the schedules of their development projects.

This is he Most Powerful Tool for Engineers:

High Precision Inspection: Our ultra-high-resolution inspection capabilities ensure meticulous examination of PCB SMT/SMD assembly components, including BGAs and CSPs.

R&D Support: These advanced inspection systems provide crucial support to R&D engineers, facilitating accurate diagnosis and swift progress in project timelines.

Industry Applications and Services

Our PCB/CCA assembly services cater to various industries, including defense, medical, communications, industrial, commercial, and automotive sectors. Medical device manufacturing is a major focus. We also offer off-shore competitive production options in Taiwan for high-volume needs.

Commitment to Quality and Timeliness

At Sparqtron, we prioritize quality and reliability in every project. Our PCB and CCA services adhere to stringent quality standards and industry certifications, including ISO 9001, ISO 13485, and IPC-A-610. We implement rigorous quality control measures throughout the manufacturing process to ensure that every product meets or exceeds customer expectations.

Sparqtron is renowned for consistently delivering high-quality PCB/CCA assemblies on time, earning our clients' trust for reliability. We pride ourselves on responsive service, swiftly addressing complex printed circuit board assembly requirements with effective solutions.

Customer Support and Collaboration

Our dedicated customer support team is available to assist you at every stage of your project. From initial consultation to final delivery, we work closely with our clients to understand their unique requirements and provide tailored solutions. Our collaborative approach ensures seamless communication and successful project outcomes.

We Accelerate your Products' Time-to-Market

Sparqtron is a proven expert in helping customers achieve rapid time-to-market for their products. With our highly knowledgeable and experienced team, we specialize in material management, PCB assembly, quick-turn prototyping, and new product introduction (NPI). Our quick turn services, often completed in less than 24 hours, ensure that your products are delivered to market faster than ever before, providing a competitive edge in today's fast-paced electronics industry.

Success Story: Thanks Mail from a Top Tier Customer

I am writing to express my appreciation for the outstanding support that Sparqtron has provided to our project over the past year.

From the beginning of the project, Sparqtron has been extremely helpful in every way possible. Your team has been instrumental in material preparation, DFM, and has shown great flexibility when it comes to production scheduling. I want to extend my gratitude to the Engineering, Production, Purchasing, and Stockroom teams for their contributions to the project.

Thank you again for your outstanding support and for the excellent work done by the Sparqtron team. I look forward to continuing our partnership and achieving further success together.

Environmental Responsibility

We are committed to environmental sustainability and compliance with global environmental regulations. Our lead-free and RoHS-compliant assembly processes minimize environmental impact, and we continuously seek ways to reduce waste and improve energy efficiency in our operations.

Request for a Quote for PCBA / CCA Assembly

Please send us the following information; we will send you the quotation very quickly.

Consign Project |

Turnkey Project |

BOM with AVL and location in excel format |

BOM with AVL and location in excel format |

Complete gerber file in standard 274X format |

Complete gerber file in standard 274X format |

PCBA assembly drawing in searchable PDF format |

PCBA assembly drawing in searchable PDF format |

PCB drawing in searchable format |

PCB drawing in searchable format |

XY data / placement file |

XY data / placement file |

CAD file and schematic (Only for flying probe test is required) |

CAD file and schematic (Only for flying probe test is required) |

Test procedure and estimated time (Only if functional test is required) |

Test procedure and estimated time (Only if functional test is required) |

FAB penalization information or drawing (Only required for production) |

Any other special instructions |

FAB penalization information or drawing (Only required for production) |

Any other special instructions |

Any other special instructions |

|

Requrst for a Quote

User Guide for a Lead-Free/RoHS-compliant PCB assembly

- Printed Circuit Board/Circuit Card: Make sure to have your printed circuit board vendor fabricate boards for lead-free / RoHS compliance. Make sure the PCB board manufacturer uses materials that can withstand the additional heat and can make multiple passes through processing without problems.

- Components: Your Bill-of-Materials must specify only RoHS compliant parts. The components in your kit must all meet lead-free and RoHS standards.

- High-Temperature Considerations:

Even for RoHS-compliant components, some of them cannot sustain high temperature. Please make sure to notify us if any component is heat sensitive.

- Ball Grid Arrays: Ensure the solder balls of the BGA are lead-free type. Soldering a lead-based solder ball BGA at lead-free reflow temperatures will fail.

- Moisture Sensitivity: Ensure components are kept in RoHS compliant storage packaging to prevent moisture. If any unopened package exceeds the expiration date or is being opened, these components will need to be properly baked to remove the excess moisture before manufacturing.

By following these guidelines, you can ensure your printed circuit board assemblies are both RoHS-compliant and reliable.

What is a Printed Circuit Board Assembly (PCBA)?

Printed circuit board assembly, also called PCBA, is the process of soldering or assembling electronic parts to a printed circuit board (PCB).

What is Surface Mount Technology (SMT)?

Surface Mount Technology, or SMT is a printed circuit board assembly process for SMD electronic components. SMD components do not have leads or legs. They are mounted on the surface of the circuit board. The equipment, electronic components and other soldering materials used in this assembly process is different from those used in the thru-hole soldering manufacturing process.

What is Through-Hole Technology (THT)?

It is also called "thru-hole." It is the mounting scheme used for electronic components that involves the use of leads on the components that are inserted into holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side either by manual placement or by the use of SMD devices.

What is a ball grid array (BGA)?

A rectangular or square array of solder balls placed on one surface.

What is a Surface-Mount Device (SMD)?

An electronic device made for mounting or placing electronics components directly onto the surface of printed circuit boards (PCBs).

What is a Package on package (PoP)?

This is a technology allows for higher component density in devices, such as mobile devices. It is an integrated circuit packaging process to combine vertically discrete logic and memory ball grid array (BGA) packages. Two or more packages are stacked together via a standard interface to route signals between each other.

What are the common questions regarding PCB Assembly?

Queries often cover minimum order quantities, response times, and service specifics for manufacturing.

What are the types of PCB Assembly?

There are two types: (a) Surface Mount PCB Assembly (SMT): Components are mounted directly onto the surface of the board. (b) Through-hole PCB Assembly: Components are inserted through drilled holes and soldered onto pads on the opposite side of the board.

What is the PCBA process?

It involves manufacturing stages like solder paste application, component placement, soldering, inspection, and testing.

How do I select a good PCB board manufacturer?

Consider factors such as quality standards, capabilities, lead times, cost-effectiveness, and communication channels.

What are the different types of PCBs?

Printed circuit boards come in various forms tailored for diverse applications, such as single-layer, double-layer, and multilayer boards.

What files or documents are required for printed circuit board Assembly?

Gerber files, BOM (Bill of Materials), assembly drawings, and pick-and-place files are commonly required for manufacturing.

What are the basic electronic components necessary for circuit card assembly?

There are resistors, capacitors, inductors, diodes, transistors, etc.

CCA versus PCBA: What's the difference?

PCBA (Printed Circuit Board Assembly):

Involves assembling individual components onto a printed circuit board (PCB) to create a functional unit.

PCB is a blank circuit card before assembly.

The term PCBA is commonly used in the electronics industry.

CCA (Circuit Card Assembly):

Comprises multiple PCBs assembled together to form a complete electronic circuit.

CCA encompasses the entire process of assembling electronic components onto a PCB.

Used interchangeably with PCBA in some contexts but signifies a broader assembly.

Difference:

PCBA focuses on assembling individual components onto a single PCB.

CCA involves assembling multiple PCBs to create a more complex electronic circuit.

What are the environmental considerations in PCB manufacturing?

PCB manufacturing has significant environmental considerations, including: Chemical Waste, Air Emissions, Waste Management, Energy Consumption and End-of-Life Considerations.

What is the PCB Manufacturing Processes?

The PCB manufacturing process involves several key techniques and components to ensure efficiency, reliability, and high performance in electronic devices. One such technique is copper pour, where large areas of a circuit board are covered with a layer of copper to enhance electrical conductivity. Panelization groups multiple individual PCBs together on a larger panel for more efficient manufacturing. A solder mask is applied to the circuit board to shield the conductive traces, preventing unintended electrical connections and providing insulation.

During assembly, a stencil with precisely cut openings is used to apply solder paste onto the board, ensuring accurate component placement. Solder resist is another protective layer that prevents solder from sticking to areas where it shouldn’t.

Reflow soldering melts the solder paste in a controlled process, creating secure connections between components, while wave soldering involves passing the entire bottom of a PCB over a wave of molten solder to create connections with through-hole components.

Silicon wafers serve as the foundation for manufacturing electronic devices like microchips. The Institute for Printed Circuits (IPC) defines standards that categorize PCBs based on performance characteristics, known as IPC Class.

Additionally, flexible printed circuit boards (Flex PCBs) are made from materials that allow them to bend or twist, and rigid-flex PCBs combine both rigid and flexible substrates. These processes and components are essential in the manufacturing of PCBs, ensuring that electronic devices are built to the highest standards.

In summary, we offer PCBA, PCB/SMT/SMD assembly, quick-turn PCB prototype assembly, PCB printed circuit board assembly, and related services to OEM customers.

PCB Assembly & Circuit Card Assembly with

Outstanding Engineering & Manufacturing Support

Sparqtron Corporation Tel: 1-510-657-7198 EXT. 200,

eMail: info@sparqtron.com

Address: 5079 Brandin Court, Fremont, California CA 94538, USA

(San Francisco Bay Area, near San Jose, California)

The X-ray Inspection System of choice:

The X-ray Inspection System of choice: